tech

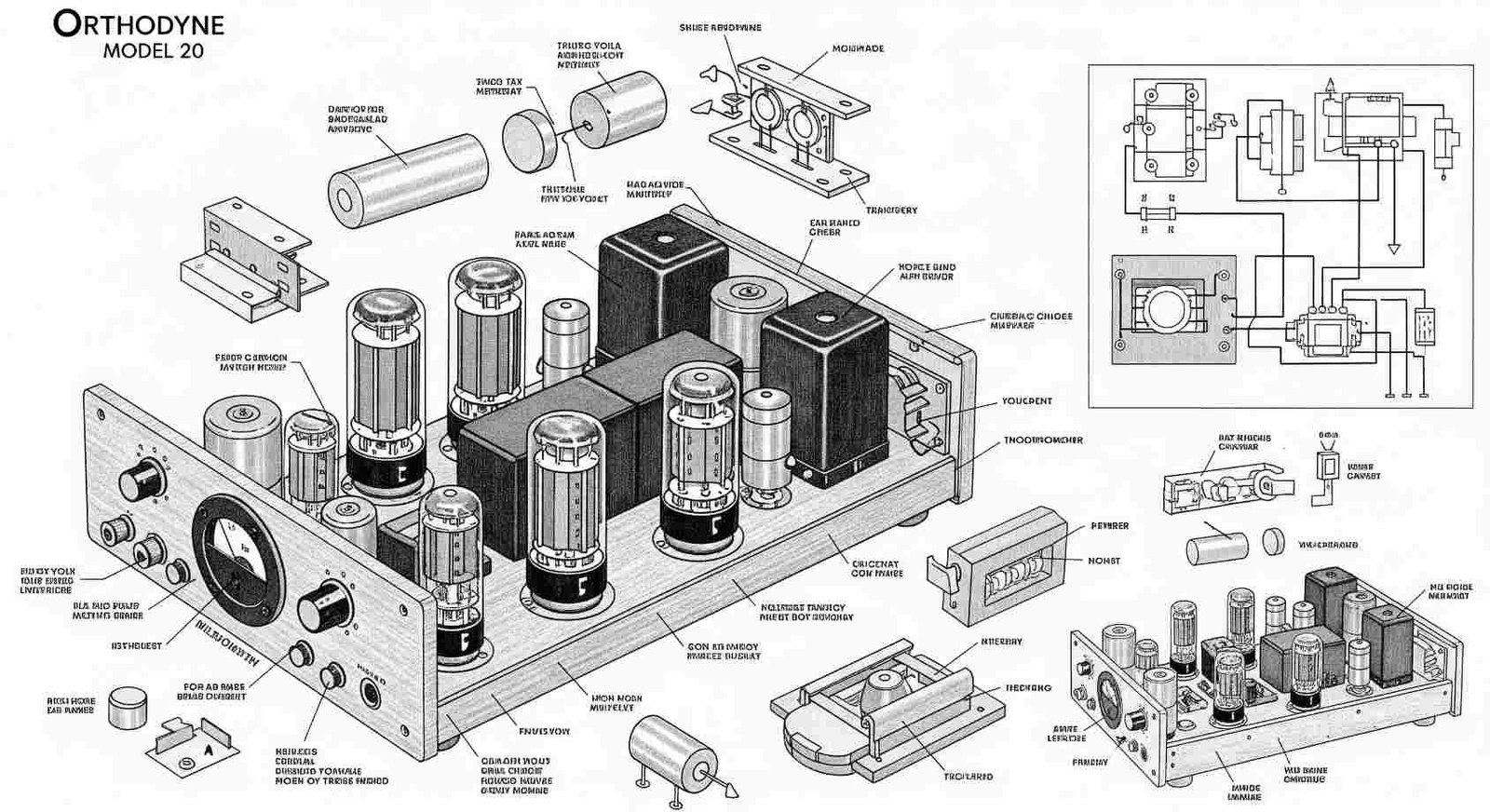

Restoring Precision: A Comprehensive Look at Orthodyne Model 20 Parts

When it comes to high-precision wire bonding equipment, the Orthodyne Model 20 stands out as a reliable, well-respected tool in the microelectronics and semiconductor industries. For engineers, technicians, and hobbyists committed to extending the life of these machines, sourcing quality orthodyne model 20 parts is essential. This article explores the different aspects of maintaining, repairing, and upgrading the Model 20 to help users keep their wire bonders operating efficiently.

Understanding the Orthodyne Model 20 and Its Legacy

The Orthodyne Model 20 is a wedge bonder used extensively in electronics manufacturing. Originally developed several decades ago, it gained a reputation for durability, precision, and user-friendly operation. While it may no longer be the latest model on the market, its robust design has made it a lasting favorite in labs and production floors worldwide.

The machine operates through a combination of ultrasonic energy and pressure, bonding fine wires to semiconductor components. As with any mechanical device, wear and tear over time require thoughtful maintenance and sometimes replacement of parts.

Common Orthodyne Model 20 Parts That Need Replacement

Keeping your equipment in top condition means recognizing the signs of wear before they cause failure. Several parts in the Orthodyne Model 20 are prone to aging or damage due to consistent usage.

Key Components:

- Transducers and Horns: Responsible for delivering ultrasonic energy, these parts are critical and must be calibrated or replaced periodically.

- Bond Head Assemblies: These may develop alignment issues or mechanical looseness, affecting bonding precision.

- Drive Belts and Bearings: As moving parts, they are subject to mechanical fatigue.

- PCBs and Sensors: Internal circuit boards can suffer from thermal stress or electronic failure.

Ensuring the availability of orthodyne model 20 parts in your inventory can reduce downtime and improve productivity when issues arise.

How to Source Genuine Parts for the Model 20

Given that the Orthodyne Model 20 is a legacy machine, finding genuine parts may be more difficult than for newer models. However, several avenues can be explored.

Authorized Dealers and Resellers

Though Orthodyne’s newer lines dominate the official sales channels, several resellers and specialty equipment vendors maintain stock or offer refurbished parts for the Model 20.

Third-Party Manufacturers

Some companies specialize in reproducing obsolete industrial components. These firms may offer compatible versions of orthodyne model 20 parts, often at a fraction of the original cost.

Before purchasing, verify part compatibility and confirm the reputation of the supplier through customer reviews or forums dedicated to semiconductor equipment maintenance.

Maintaining the Model 20 for Extended Longevity

Proper maintenance is crucial to avoiding premature part failure and ensuring consistent performance. Even simple steps can extend the operational life of key components.

Maintenance Best Practices:

- Scheduled Cleaning: Dust and debris can degrade mechanical parts and electronics.

- Routine Calibration: Maintaining the correct ultrasonic output and pressure ensures consistent wire bonds.

- Visual Inspections: Spotting frayed belts, worn horns, or cracked PCBs early can prevent major malfunctions.

Incorporating a preventive maintenance routine can help limit your dependency on frequently replacing orthodyne model 20 parts.

Modern Alternatives vs. Maintaining Legacy Equipment

In today’s fast-paced electronics manufacturing world, businesses must decide whether to maintain aging equipment or invest in modern alternatives. The Orthodyne Model 20, while reliable, may lack some features of modern bonders, such as digital controls or network integration.

Cost vs. Benefit Analysis

Upgrading to a new machine often requires a large investment in capital, training, and operational disruption. For many small manufacturers, keeping the Model 20 in service with reliable orthodyne model 20 parts remains the more financially sound option—especially when production needs are stable and modest.

FAQ

Q: Can I still find original Orthodyne Model 20 parts today?

A: Yes, though availability is limited. Look for trusted resellers, surplus equipment dealers, or firms that specialize in legacy electronics components.

Q: What parts of the Orthodyne Model 20 typically fail first?

A: Commonly replaced parts include ultrasonic transducers, horns, belts, and sensors.

Q: Are refurbished or third-party parts reliable?

A: They can be, but it’s essential to vet suppliers carefully. Ensure specifications match and look for feedback from other users.

Q: Should I upgrade or maintain my Model 20?

A: It depends on your budget and needs. If the machine still meets your production requirements, maintaining it with quality parts is often the more cost-effective option.

Q: How often should I perform maintenance?

A: Monthly visual inspections and biannual calibrations are good benchmarks, depending on usage.

Conclusion

The Orthodyne Model 20 remains a staple in many production environments, proving that quality engineering stands the test of time. For operators who choose to maintain rather than replace their equipment, sourcing dependable orthodyne model 20 parts is not just a necessity—it’s a strategy for sustainable and cost-effective manufacturing.

As long as there is demand for high-precision bonding in compact electronics, machines like the Orthodyne Model 20 will retain their value. With a thoughtful approach to upkeep, and a trusted network for part sourcing, users can continue to rely on this classic tool well into the future.

tech3 weeks ago

tech3 weeks agoExploring the World of AI Creativity Through ai-work-archives-ghaus-editz

business1 month ago

business1 month agoExploring the Rise of Sichuan Tong Dao Technology Co Ltd in China’s Tech Industry

tech1 month ago

tech1 month agoEmpowering Digital Innovation: Anantax Technologies Pvt Ltd at the Forefront of IT Solutions

tech1 month ago

tech1 month agoThe Ultimate Guide on How to Run Star Technology Modpack Server Minecraft